Intro

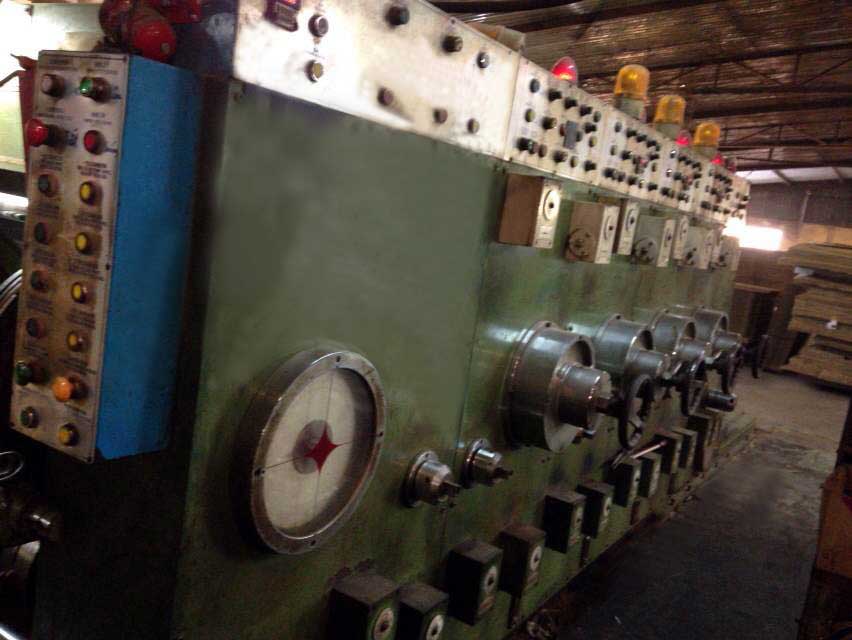

Pham Thu Co., Ltd was established in 1988 in Tan Hiep Commune, Hoc Mon District, HCM City. The factory area is about 6,000 M2 within the land area of 12,000 M2.The lines of equipment are eco-friendly founded including:

1/ The paper-machine factory: Its main products are Medium paper, Testliner paper.The 1,000 MT paper roll warehouse as raw material can especially satisfy all orders of carton boxes within 48 hours.

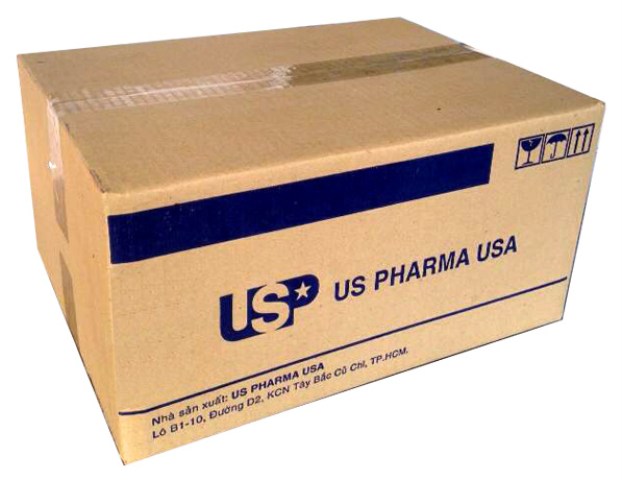

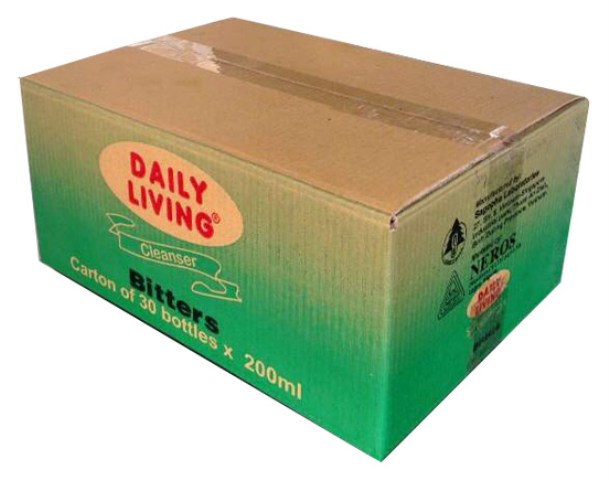

2/ The carton machines: producing 3 plies,5 plies,7 plies cardboard

3/ The converting factory: The slitting, slotting, 4 color flexo printing, rotary and flat die-cutting, glueing and stapling machines.

In addition to the main line, there is a secondary line including:

(A) The complete line of water-treatment plant: its capacity can handle 500 M3/day.The treated water is recirculated for paper making.The water effluent is rated as Class B of government environmental regulations.

(B) Two boilers: The paddy husk is used as biomass fuel to reduce greenhouse effect.The flue-gas conforms to the environmental standards.

(C) The Lab: testing the quality properties of paper materials and corrugated paperboards.The lab also assumes the task of paper layer analysis of corrugated paperboards allowing the measurement of the substance (g/ m2) of each ply of paper.These operations can allow to choose the optimum paper materials (made right in the company) which have lighter weight, better strength, and accordingly better quotations of carton boxes. (D) Printing plate division: includes:

D1/ Computer printing design.

D2/ Computer aided laser-cutting machine to make printing plate.Pham Thu Co., Ltd was established in 1988 in Tan Hiep Commune, Hoc Mon District, HCM City. The factory area is about 6,000 M2 within the land area of 12,000 M2.The lines of equipment are eco-friendly founded including:

1/ The paper-machine factory: Its main products are Medium paper, Testliner paper.The 1,000 MT paper roll warehouse as raw material can especially satisfy all orders of carton boxes within 48 hours.

2/ The carton machines: producing 3 plies,5 plies,7 plies cardboard

3/ The converting factory: The slitting, slotting, 4 color flexo printing, rotary and flat die-cutting, glueing and stapling machines.

In addition to the main line, there is a secondary line including:

(A) The complete line of water-treatment plant: its capacity can handle 500 M3/day.The treated water is recirculated for paper making.The water effluent is rated as Class B of government environmental regulations.

(B) Two boilers: The paddy husk is used as biomass fuel to reduce greenhouse effect.The flue-gas conforms to the environmental standards.

(C) The Lab: testing the quality properties of paper materials and corrugated paperboards.The lab also assumes the task of paper layer analysis of corrugated paperboards allowing the measurement of the substance (g/ m2) of each ply of paper.These operations can allow to choose the optimum paper materials (made right in the company) which have lighter weight, better strength, and accordingly better quotations of carton boxes. (D) Printing plate division: includes:

D1/ Computer printing design.

D2/ Computer aided laser-cutting machine to make printing plate.

Map

Sorry, no records were found. Please adjust your search criteria and try again.

Sorry, unable to load the Maps API.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)